Production optimization

Increasing Production by 100x Through Digital Transformation for a Ventilator Manufacturer

When the demand for ventilators rose at the start of the COVID-19 pandemic, Wavicle helped a global company that provides respiratory care solutions meet their production goals. The ventilator manufacturer needed to optimize their production process and minimize the complexity of ventilator design to meet the spike in demand by producing 600 units per day, an increase from their usual five to seven units per day.

This unique problem needed out-of-the-box thinking. Wavicle aligned with the manufacturer, their partners, and their suppliers to defy the odds and leverage data and analytics to enable the company to ramp up ventilator production to new heights and provide the ventilators needed to save lives throughout the pandemic.

Kicking off with a future-ready data foundation

Prior to the start of the pandemic, Wavicle had already worked with this global respiratory care provider to start building a future-ready data foundation to support digital transformation initiatives. This one-stop unified portal enabled leaders to evaluate business performance through a single admin console view that offers insight into revenue, order management, finance, and more.

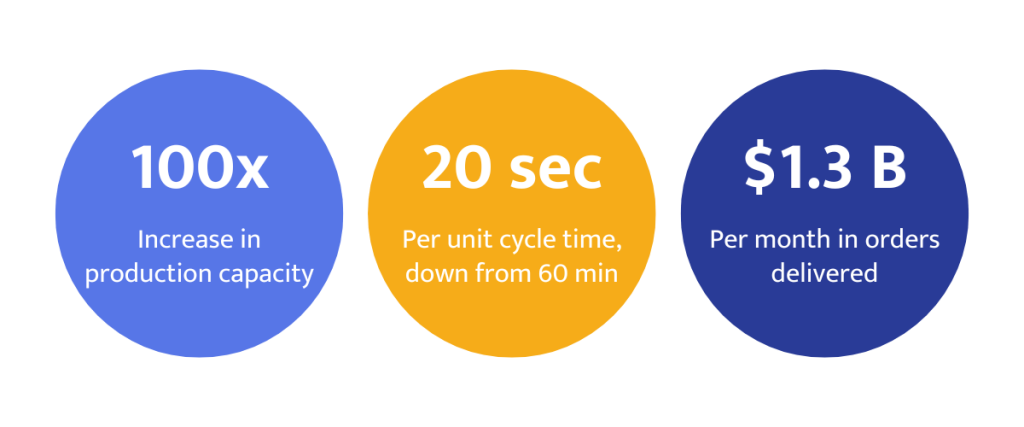

This project resulted in:

With such remarkable results, the business was ready to scale the platform globally. Then, when facing unprecedented challenges scaling manufacturing output, they tapped into Wavicle’s manufacturing experience and data and analytics expertise to deliver optimization solutions in mere weeks.

Optimizing production with data and insights

When looking to increase manufacturing throughput to meet demand, this manufacturer first needed to validate basic manufacturing numbers, dial in labor, and optimize machinery capacity. All of these initiatives required harmonized and high-quality data from across the business to provide actionable insight into key opportunities for improvement and inform the strategies that would help them meet new manufacturing requirements.

In addition to their work on the manufacturer’s data foundation and business dashboards, Wavicle’s team evaluated plant blueprints and deployed a small unit of consultants on the production floor. The team understood the needs of the business and used analytics to fine tune the production process and other workflows to skyrocket production without significant additional investments.

This process included integrating IOT-enabled machinery on the ventilator production lines to extract real-time information from on-premises to the cloud and delivering required data points and insights that captured the bottlenecks and efficiencies of the process. This approach enabled Wavicle’s team to work with the ventilator manufacturer to improve production output and deliver more respiratory care products to hospitals worldwide.

Accelerating transformation to achieve rapid results

Leveraging the insights provided by the data, Wavicle and the manufacturer found new ways to:

- Increase production capacity to manufacture more products in the same unit of time without investing in new infrastructure or machines.

- Reduce production cycle times to produce ventilators faster and maximize the throughput of their existing machinery.

Wavicle’s data and analytics experts empowered the manufacturer to achieve:

Overall, Wavicle’s partnership with the global respiratory care solutions provider enabled unprecedented levels of success, allowing the team to respond quickly and effectively to the pandemic-induced demand for ventilators.